DIRECT THERMAL VERSUS THERMAL TRANSFER

How do direct thermal and thermal transfer labels work?

Direct thermal labels are designed to react with heat. They come into direct contact with the print-head (through the thermal label printer) which heats up and reacts with the surface of the thermal label to create the print. The nature of this material means it is ideal for short-term print solutions.

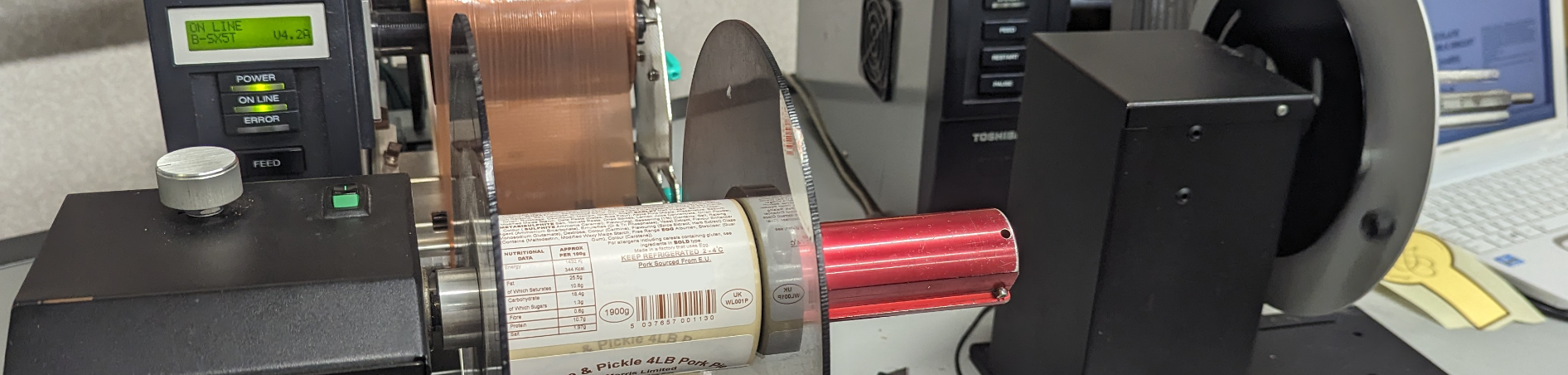

Thermal transfer labels offer a more robust long - term option. They require thermal transfer ribbon to print with. The ribbon runs between the label material and the print-head of the thermal label printer. Heat from the print-head burns the ribbon onto the label, creating the print. Using thermal transfer labels reduces print-head wear.

How do direct thermal and thermal transfer labels work?

Direct thermal labels are designed to react with heat. They come into direct contact with the print-head (through the thermal label printer) which heats up and reacts with the surface of the thermal label to create the print. The nature of this material means it is ideal for short-term print solutions.

Thermal transfer labels offer a more robust long - term option. They require thermal transfer ribbon to print with. The ribbon runs between the label material and the print-head of the thermal label printer. Heat from the print-head burns the ribbon onto the label, creating the print. Using thermal transfer labels reduces print-head wear.